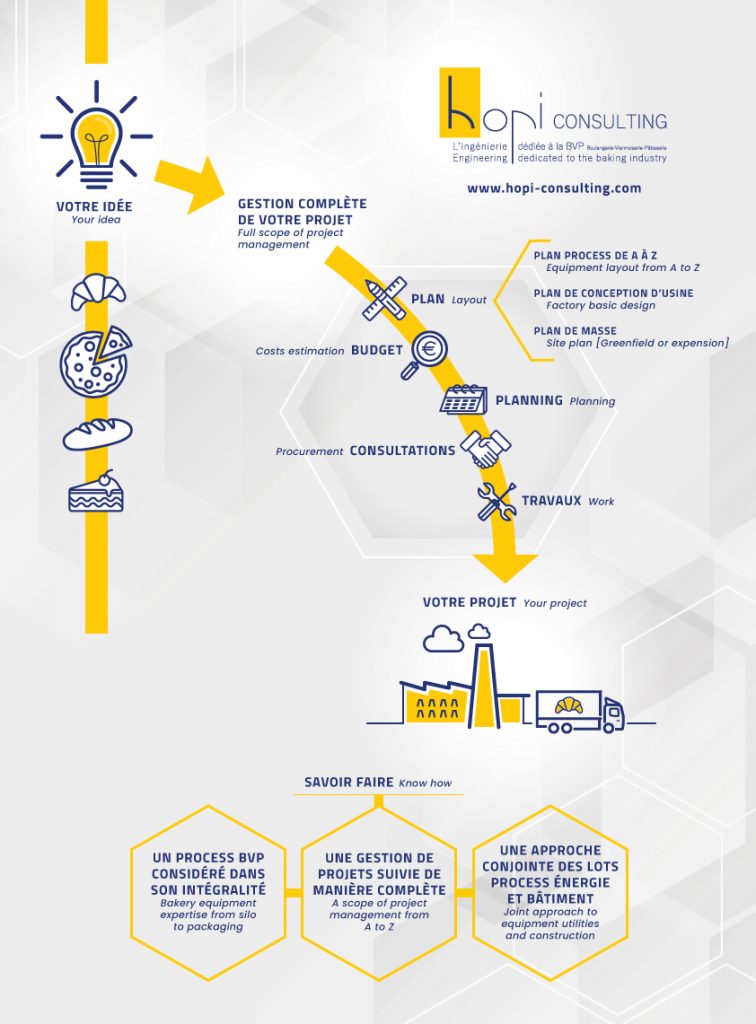

Discover Hopi Consulting, a consultancy fully dedicated to the bakery industry. The guaranty to find a tailor-made solution for your project management by combining bakery process expertise, construction, and utilities knowledge. The best way to offer dedicated and complete technical solutions.

What is true in many industral situations is that technical regrets come from poor matches between the need and the technical solution that has been adopted. This is why it is so important to proceed in 2 steps :

- first focus on the definition of the need,

- then find the solution dedicated.

Especially when technical fields are full of solutions and suppliers. That is why it was important to focus in this article on the paletts racking options.

There are major ways to deliver raw materials and ingredients in the bakery industry : in bulk or on palett (made of plastic or wood). Finished products are always shipped on paletts.

Therefore, it is crucial to find the best solution to rack all these paletts according two targets : flexibility and cost.

The best option to store on paletts raw materials and ingredients is fixed pallets racks clearly meaning that their carrying structures are static. They can be found in ambiant warehouses but also cold ones. This option is dedicated to store a large range of materials on paletts : bags (salt, improvers…), big bags (flour, sugar…), liquid containers (yeast, sourdough…) and other materials shipped on pallet (plastic or wood).

The locations of the pallet racks for the operators are all and always accessible for the operator using aisle to reach on side from the other. This option is the easiest and cheapest solution.

There are solutions to optimize the storage of pallets and save space on the floor. Using massification, double/triple depth storage options and accumulation storage options can be very good solutions.

But becareful, these options are very nice if the warehouse is composed of a few number of types of materials and when flexibility is not a crucial issue. Because only the pallets located at the front are accessible. This is why these solutions are perfectly suited when the number of product references is low.

Again, nothing is more importance than focusing on the needs during the first step of the project. And only then, starting to select the best storage options according to the needs and the target of flexibility.

Pallets racks can also be mobile thanks to back an forth movement of the aisles. The massification of the pallets is considerable as well as the gain of space in the warehouse.

However, it is crucial to pay attention on the low level of flexibility of these installations and to their maintenance over time for perfect operation.

The storage of the pallets in the bakery industry can be also highly automated thanks to pallets shuttle or stacker cranes. This solutions bring very high capacities with very low needs of labor.

They allow in an autonomous automated way, with shuttles, to stack and unstack pallets without any pallets driver operator. Computer intelligence, such as warehouse management system – WMS, is essential in this type of installation: traceability, link with an enterprise ressource planning – ERP, degraded mode…

These highly efficient installations only find their success in specific situations. They bring efficiency but also challenges ! the modes of identification and reading of the pallets which enter and leave must be fluid, the software exchange protocols are clear and well defined, the management and interfacing with the operators are fully operational, the fire protection systems (sprinkling zand smoke detection) are taken into account and the upgrades of the installations are anticipated for tommorow…

In any case, it is the budget allocated to the project, the available storage area, the expected number of pallets stored, the input and output flows and the number of item references that allow you to make the right choice between all of these technical solutions. While immediately taking into account possible future developments but also building height regulations or insurance and fire protection constraints. This is the ideal opportunity to anticipate such a project by working on a industrial strategic plan mission to lay down the data and not forget anything once the project has been launched.

Did I tell you about the importance of the pre project study and defining the need…