Introduction

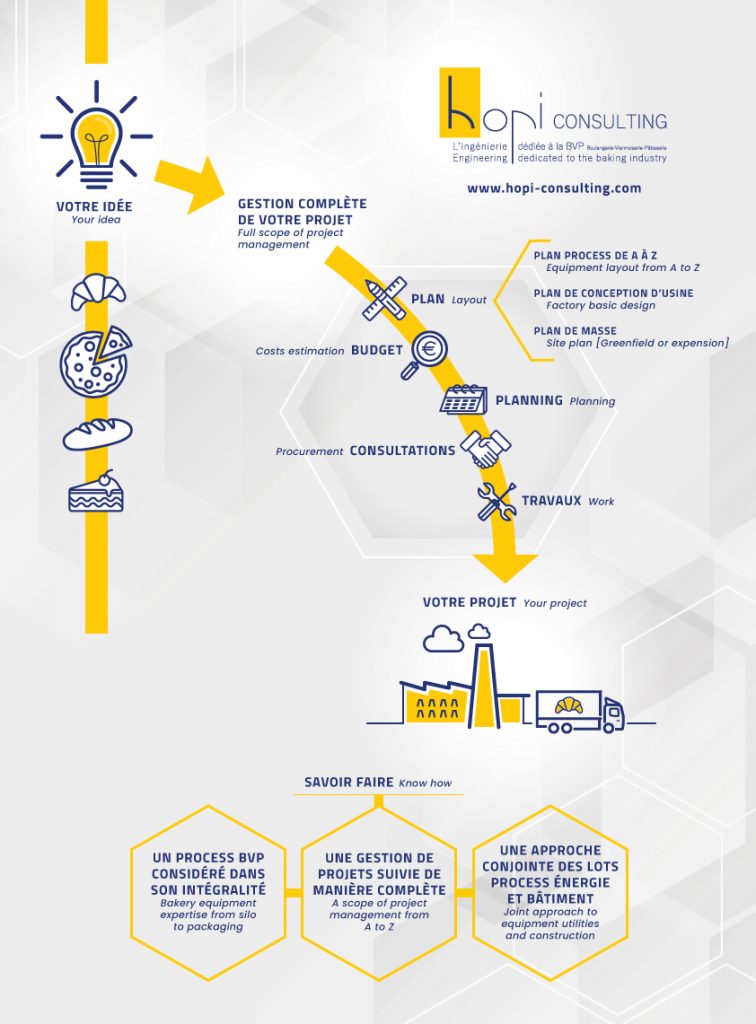

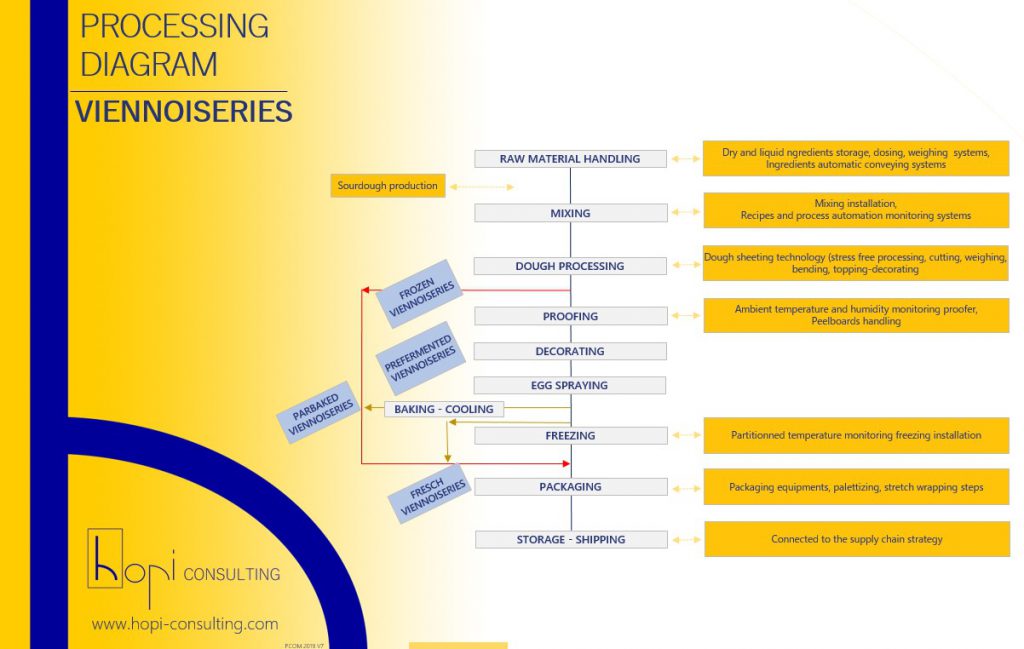

Are you looking for a clear and understandable description about how viennoiseries are produced in industry ? Here is a step-by-step description of the sheeting line process, enabling large-scale and continuous production of various bakery products such as viennoiseries, croissants, pain au chocolat, puff products…

This article covers the whole production process: from the storage and dosing of the raw materials, to kneading, dough make up, baking, cooling, freezing, packaging steps and at the end shipment.

This is a technical overview of how are produced two ranges of puff products. The ones requiering yeast and a proofing stage as viennoiseries, croissants, chocolate dough…And the ones made of dough without yeast and a proofing stage, puff products, epiphany cakes, rolls…

To make this article easy to understand we have intentionally decided to focus on some technical details which are dedicated to specific bakery products made by sheeting lines. For instance, viennoiseries are sometimes sold raw, while other products are partially proofed (“Ready To Bake”) or fully baked. Storage conditions also vary based on sales requirements: fresh or frozen.

Let’s highlight a general bakery production diagram without keeping in mind the endless list of all possible production options to make bread.

Production step by step description

1 - Raw materials storage and dosing

This is the first step of the production process when raw materials start to enter in the industrial factory environment. This preliminary stage is raw materials storage. There are different storage options according to the conditions of delivery. On one hand, dry ingredients (seeds) and powders (flours) can be delivered either in bags (20 kg in France today) or in larger single quantity (1-ton big bag, for example), always placed and handled on pallets. They are stored in many levels of racks located in a dedicated warehouse. Air conditions warehouses vary based on raw materials requirements (ambient or cold conditions). One the other hand, some raw materials can be delivered in bulk tankers to be stored in silos or tanks able to hold several tons of flour, sugar, or certain liquid ingredients as well as chocolate or yeast.

Liquid ingredients (syrups, yeast, sourdough, oils, for example) are handled in different ways based on the size of the delivery batch: from a few liters drum up to 1000-liter container). As the dry raw materials, liquid raw materials can be stored in a warehouse in pallet racks or in bulk tanks.

Then, these ingredients are dosed according to the recipe of the finished product. This dosing stage may be carried out fully automatically thanks to weighing hoppers or manually with scales.

You can find dedicated articles about these technical topics in Hopi consulting technical blog dedicated to the baking industry.

2 - Kneading

Many bakers agree to say that this is the key step in production of bakery products! And this is true, this step is far from just a mixing stage. Kneading starts when ingredients are dosed in the bowl of the mixer. First minutes consist in mixing these ingredients. But kneading isn’t only mixing, it is a bakery crucial stage including texturing the wheat gluten network in the dough and developing flavors and aromas.

At this stage, fat (butter or margarine) is still not added in the mixer bowl, the fatless dough is called “détrempe” in French.

Kneading brings a lot of energy to texture properly the dough, resulting significant heating effects. It is time to focus on a crucial parameter that must be put under control: dough temperature. Even if this is always true in bakery, temperature is even more important regarding sheeting lines process. Because the art of sheeting dough is to be able to keep separated the fat and the dough all along production. By keeping the dough as cold as possible, warming effects are limited so the migration of hot melt fat inside the dough.

Today, industrial mixers are designed to put under control dough temperature. Most of the time mixer bowls are composed of a double jacket. A liquid refrigerant such as glycol circulates in this area outside of the bowl and cool its sides so the dough next to. In addition, raw materials are added as cold as possible thanks to cold storage conditions or cooling stages (for flour, for example). Water added in the dough also plays a crucial role. Thanks to refrigerant exchangers, tap city water temperature is decreased and targeted as cold as possible, often close to 1-2°C. Another possibility is to incorporate ice to cool the dough.

3 - Make-up line

Two options are possible to carry out a sheeting dough process. The first way is a mix of craft bakers and industrial methodologies. It is highly inspired by the artisanal method and its tools, such as the automatic laminator. The second way is more industrial and presents highly automated machinery and operations.

The goal is to transform a mass of dough and fat into a finished product with the right size, weight, shape, filled and decorated as expected. The first step to produce sheeting dough is to incorporate fat into the dough coming from the mixer. This is the time when the fat mass needs to be “enclosed” within a dough external skin. In the preliminary seconds of this process, the dough may be compared to a postal envelop with fat inside playing the letter. The challenge is to keep separated the fat inside this external skin of dough all along the production process.

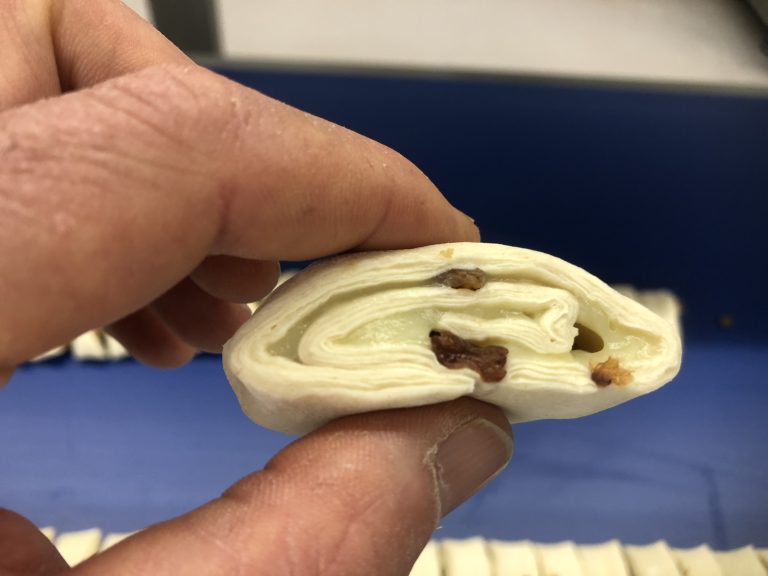

Then comes the sheeting process consisting in flattening this big mass (like using a rolling pin) in a thin continuous flow of dough. And to fold up this dough to superimpose layers of fat and dough. This stage consists in repeating these operations of flattering and then folding as many times as possible to reach a strong number of layers of fat and dough. Hence the name of “mille-feuille” in French as “thousand layers”. But the challenge is to keep each layer of fat separated to each layer of dough. Cold temperature helps to put under control this demanding effort.

These long make-up lines (up to 100 meters long!) are composed of conveyor belts, cooling tunnels and specialized tools to flat, fold up, shape, decorate and fill the products. One final stage is eggs spraying to give a nice color crust in the oven. And this is how frangipane filled epiphany cakes, apples turnovers, cream sweet products, croissants…are produced.

4 - Proofing

This ancestral process allows bakery products to gain volume and flavor. The yeast and possibly sourdough introduced during kneading release fermentative gases trapped by the gluten network in the dough, allowing it to rise. The industrial proofing chamber is an enclosure, a tunnel, or a continuous spiral through which products circulate. Proofing time, temperature and humidity are under control to ensure the regularity and quality of the products.

This step only concerns dough requiring yeast, as well as viennoiseries (croissant for example). Puff pastries do not have yeast in their recipes and therefore do not require a fermentation step.

It is during this step that the quality of the previous work becomes evident. The gases are trapped in the dough cavities while remaining separated from the fat. The beautiful visual of the lamination that we know is under construction…

5 - Baking

This is the stage where the delicious smell of bakery products appears! Here, thermal effects and fermentation processes give the product its final volume but, most importantly, the distinctive visual of the sheeting methodology. If the dough and fat have remained separated until now, baking causes the fat to melt, creating expansion cavities for the fermentation gases. Unfortunately, if the two phases have migrated, the cavities will be less distinct, affecting the product’s visual and development quality.

Industrial ovens are ventilated ovens with rotating trolley racks or tunnels through which the products are conveyed. Again, the parameters of baking time, temperature, and humidity, as well as thermal transfer modes, are precisely managed for optimal quality, perfect production efficiency and energy savings.

6 - Cooling

This step allows the baked products to cool down from 90°C to 25°C. It is essential that products cool down in preparation for freezing or packaging operations; otherwise, the risk of degrading the final product quality would be very high. Products are conveyed in an environment where the air is cooled to capture the products’ heat and thus decrease the temperature. Hygiene at this stage is crucial to optimize shelf-life product. That is why climatization design and cleaning operations are important during this step.

The challenge is to extract the humidity and remain water concentration in the product. Because humidity varies significantly inside a baked bakery product: its center (the crumb) is more humid than its skin (the crust). The goal of this cooling step is to limit water migration to the surface to avoid risks of degrading the product’s crispness and its shelf life. This is a very demanding operation. Some cooling technologies use vacuum solutions to decrease air pressure during the cooling step to optimize humidity migration.

7 - Freezing

Some supply chains solutions require frozen finished products (heart product temperature is close to -20°C). Once again, products are conveyed through a refrigerated enclosure with monitored passage times and cold temperature to freeze them while preserving their taste and organoleptic qualities. Industrial freezers are either discontinuous or continuous and composed of refrigerant exchangers and fans.

8 - Packaging

This stage is easy to understand! Packaging is composed of different steps. The first stage, called primary packaging consists in wrapping the product in a first skin of packaging. This first skin has two goals: marketing and hygiene. The secondary packaging consists in packing different products in boxes to optimize the supply chain and the delivery requirements. The last stage is the palettization of boxes on pallets. Then these pallets are stored in warehouses before being shipped. Labelling operations are carried out as soon as identification and traceability need to be printed.

Many packaging solutions exist based on customers’ needs and innovation. Therefore, many technologies are available: automated and robotic loading installations, automatic horizontal or vertical packaging machines… diversity and innovation are essential at this stage! And a new challenging demand is to reduce labor operations.

9 - Storage and shipping

This is the final step. The products are ready to leave the factory. Packed products are stored in warehouses in pallet racks. Based on supply chains options, air conditions in warehouses may be ambient, cold, or frozen conditions. This stage is crucial for the traceability of products and logistical data including product flow management and WMS (Warehouse management software). Depending on supply chains requirements, products may be stored for varying durations, from a few days up to several months. Upon leaving the shipping dock, the product completes its industrial manufacturing process.

This article was written by Hopi consulting, “Engineering dedicated to Baking Industry”.

Discover more articles on the Hopi consulting blog dedicated to the bakery industry.