When it comes to kneading solutions, the range of options is vast, and the market for bakery and snacking industry is filled with numerous technical solutions. Choosing the right mixing technology, the number of machines, their capacities, layout, and sizing are all fundamental questions for this crucial step in the bakery industry production process—whether for bread, viennoiseries, pastries, pizzas, and more. All these bakery and snacking products require ingredient mixing, and dough texturing is particularly essential to strengthen the gluten needed for the fermentation stage. Selecting the right kneading solution can therefore be a key decision.

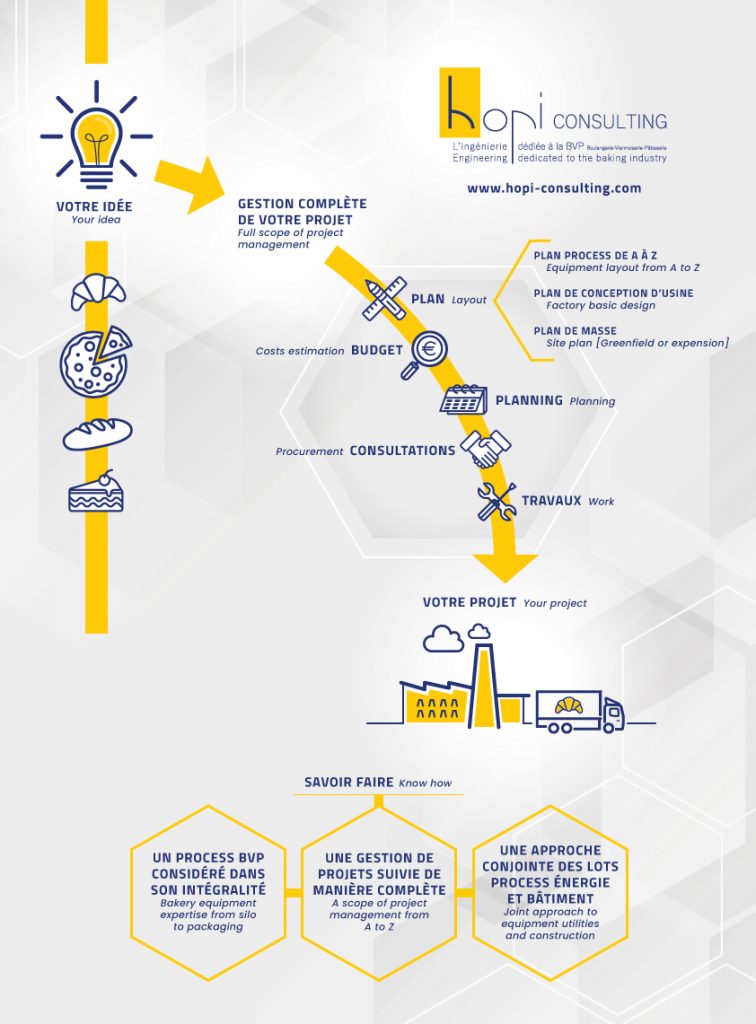

If you are looking for kneading solutions in the bakery industry sector, you will quickly realize that the choices are vast and varied. But which one truly fits your needs? A technical solution may initially seem appropriate, only to turn out to be a poor choice—both in terms of budget and technical functionalities. This is where Hopi Consulting comes in: we help you understand your specific requirements and identify THE technical solution that truly matches YOUR needs, ensuring you make the right choice. Our impartial and independent approach is entirely focused on finding the best solution for your project.

So, what is your kneading method?

Table of contents

Different types of dough, different kneading equipment…

Many professionals in the bakery industry sector will tell you that baking is an art applied to a living material: dough. It is therefore easy to start this article by emphasizing that in baking, there is no single ideal solution. Indeed, since success depends on a combination of favorable factors—such as the choice and quality of ingredients, control of time and temperature, selection of machines, and other expertise—it is clear that the key to successful kneading cannot be reduced to a single determining factor.

The same applies to choosing the right kneading equipment technology. A single machine cannot encompass all existing technologies like a Swiss Army knife: intensive kneading, gentle kneading, hot dough, cold dough, low production rates, high production rates, flexibility, specialization…

In the baking industry, many roads can drive to the same point, selecting equipment is therefore a challenge.

And to make things even more complex, you’ll find that each kneading solution and technology can be further subdivided into options that may or may not be relevant depending on the situation. Different solutions can therefore meet the same need. So, take this article with the necessary baker’s perspective, and most importantly, share your comments and experiences after reading!

Selection of the mixing arm

Dipping arm mixer

This mixer is undoubtedly the piece of equipment that most closely replicates the ancestral gestures of a baker. Indeed, the movement of the two arms plunging into the dough mirrors the mechanical motion of our predecessors, who kneaded dough with the sweat of their brows. This solution remains the most traditional mechanized method for dough handling in baking.

Its advocates will tell you that nothing surpasses it in terms of dough texturing and hydration. It is particularly well suited for highly hydrated bread doughs, often rich in sourdough, requiring

long kneading times, relatively slow kneading speeds, and gentle production processes incorporating autolysis and bassinage phases. This technology is ideal for traditional large-format breads with a cream-colored, highly open, and airy crumb, along with a thick crust. The main drawback of this choice is its difficulty in achieving high production rates and in quickly and intensively texturing the dough. In such cases, multiple machines must be used, which can significantly impact the overall project cost.

Oblique arm mixer

This mixer remains a traditional choice that many bakers appreciate for offering a better “quality/productivity” balance compared to the diving arm kneader. The oblique-shaped mixing arm interacts with the dough more efficiently, allowing for shorter kneading times while promoting dough hydration. Depending on the kneading parameters, this technology accommodates a wider range of products, from very traditional bakery items to more conventional ones with a firmer, less hydrated crumb (such as classic and traditional baguettes or specialty breads). However, it shares the same drawback as the diving arm kneader: it is far less efficient than the following technologies for products requiring more intensive kneading and high production rates.

Spiral arm mixer

This kneading technology, also known as the “pig’s tail” mixer due to its corkscrew-shaped shaft, was developed for bakery products with a tight, white crumb and for viennoiseries. These machines enable intensive kneading, efficiently and rapidly texturing the dough. Their main advantage lies in their versatility, as they can knead a wide range of bakery industry products while also adapting well to high-productivity processes, such as laminated doughs for viennoiseries, pizza dough, and, of course, conventional bakery products. They are perfectly suited for high-output production lines and bakery products like white-crumb baked or parbaked breads, pizzas, soft breads (buns, sandwich bread), and viennoiseries.

To push productivity and intensive kneading even further, it is possible to add two or even three shafts to further increase kneading intensity. This is a true powerhouse, delivering excellent productivity ratios at the kneading stage.

Kneader with specific arm

Modern times in baking now offer other shaft designs based on technical and energy studies. Indeed, the kneading process can be modeled by measuring the energy incorporated into the dough over time, with the goal of finding the most optimized and efficient solution. The leading manufacturers of kneading equipment now offer their own mixing arm designs. In theory, each design should perfectly adapt to the different kneading needs: gentle, intensive, fast, slow…

Selection of the bowl

Kneader with outgoing and rotating bowl

This technology is the most traditional and closest to the ancestral process. The principle involves using a bowl that holds the dough and rotates around a central axis. The mixing shaft descends into the dough and also rotates at a defined speed, allowing the dough to be worked. Once the kneading cycle is complete, the bowl moves out of the kneading station and is often integrated into a bowl lifter, which empties the dough into a receiving hopper.

For safety reasons and to allow for automatic ingredient addition, the bowl is no longer fully open. However, this solution remains reassuring as it allows bakers to visually monitor the dough throughout the kneading process.

This technology is adaptable to almost all bakery products, making it a safe and reliable choice.

Vertical mixer with fixed bowl

Inspired by traditional technology, it is now possible to find kneaders similar to those described above, but with a fixed bowl. In this case, the bowl may rotate or remain stationary, while one or more mixing arms ensure the dough’s movement. This technology is equipped with a bottom discharge system, which is the only way to empty the dough.

Horizontal kneader

Horizontal kneaders, as their name suggests, feature a horizontal kneading trough. Instead of a traditional bowl, they use a cylindrical-shaped volume. The horizontal kneading shaft is adapted to this elongated shape, often designed as a ribbon-like structure. One key advantage of this technology is its easy dough discharge: the tank tilts, allowing the dough to fall into a hopper or onto an evacuation conveyor.

Horizontal kneaders are well-suited for intensive kneading, especially for soft-textured products with a fine, tight crumb, such as sandwich bread, hamburger buns, and white-crumb breads, as well as for laminated doughs used in viennoiseries. This horizontal technology also allows for bowl cooling, further optimizing heat exchange during intensive kneading phases. However, this cooling option is now also available for vertical kneaders.

Selection of the kneading technology

Kneading by batch

Batch kneading indicates that the kneading cycles follow one another and are perfectly independent of each other. They follow one another throughout the day’s production schedule.

Continuous kneading

This option, in contrast, produces dough continuously, without the ability to observe successive kneading cycles. Instead, there is a constant flow of dough emerging from the kneading chamber.

This modern mixing method is exclusively used with horizontal kneaders, where temperature control is a critical factor. It is always paired with a double-jacketed glycol-cooled bowl, ensuring intensive kneading for the production of very white, tight-crumb products, such as sandwich bread, hamburger buns, and laminated dough for viennoiseries.

Selection of the emptying solution

Continuous kneading

The continuous mixer offers a fairly obvious emptying solution. In fact, the dough escapes at one end of the horizontal cavity of the mixer. It will be cut using a guillotine and then conveyed on a conveyor belt to the production line.

Batch mixing using bowl elevator for emptying

This is the most traditional option. Once the kneading cycle is complete, the bowl is moved—either automatically or manually by an operator—to an additional piece of equipment: the bowl lifter. As the name suggests, this equipment lifts the bowl to a sufficient height (between 1.50 m and 3.50 m) to pour the dough into the hopper of the production line. Once the operation is complete, the bowl returns to the kneading station for a new cycle.

Batch Kneader with bottom discharge

With this option, the kneader’s bowl opens from the bottom, allowing the dough to fall by gravity onto a conveyor belt positioned below. This solution eliminates the need for a bowl lifter, which is an additional component that can introduce technical and layout constraints. However, this choice presents a cleaning challenge, as the lower conveyor can quickly become soiled.

Other key options that will arise

It is important to find the best compromise regarding the batch size of the dough.

The advantages of a large batch are a reduction in the number of kneading cycles and lower investment costs. The disadvantage is the waiting time before the dough moves onto the production line, which can impact product quality and facility layout.

Conversely, choosing a smaller batch size has the advantage of a shorter dough waiting time on the line, as more batches are produced per hour. However, this less favorable cycle time may require investing in more equipment, leading to higher costs. Facility layout constraints can also become more complex.

Setting a 20-minute complete cycle time—including ingredient dosing, dual-speed kneading, and dough discharge—ensures safe and reliable decision-making.

The choice of the number of machines is directly linked to the batch size of the dough. The more machines there are, the smaller the batch sizes will be. The advantage of having more machines is operational security in case of a breakdown, with the best example being the choice between one or two machines. Additionally, facility layout may influence the decision to opt for fewer machines with higher capacity.

Be mindful of additional costs, especially with automated ingredient dosing. The extra cost can be significantly higher if ingredients are supplied to multiple machines instead of just one. The budgetary and technical impact can be considerable.

This option will prove crucial in the case of intensive kneading, where dough temperatures are critical. In this case, the choice of a double-jacketed cooling system (usually with glycol water) is important. This ensures that the heat generated by intensive kneading is controlled and limited.

These technologies are perfectly suited for soft products like sandwich bread or hamburger buns, as well as for laminated doughs used in viennoiseries.

There are horizontal kneaders that offer the possibility of vacuuming the kneading environment, further intensifying the dough’s texturing to achieve even finer and more uniform crumb.

These technologies are perfectly suited for soft products like sandwich bread or buns, which require extremely consistent crumb.

When choosing a kneading machine, it is important to consider the incorporation of ingredients, especially flour, water, but also minor ingredients (salt, mixes) and other liquids (levain, oil). The choice to automate the ingredient incorporation directly into the kneader will help achieve reliable and precise weighing objectives. Thanks to automatic dosing, ergonomics (eliminating manual lifting) is also improved.

Obviously, these solutions come with a cost, which should be considered alongside the cost of the kneader machine before making any decisions. It is crucial to match the mixer’s capacity expectations with the solutions offered for ingredient dosing.

If the decision is made to add ingredients manually, there are numerous solutions available that provide effective results in terms of ergonomics, operator safety, and productivity. Examples include connected scales, automatic transfers of manual weights into the kneader, and weighing preparation boxes.

The location remains a fundamental point in the choice of the mixer. Often, special constraints on the ground but also at height limit the choice of technologies. It is crucial to study the possibilities offered by the room in terms of adaptation, such as changes in the location of partitions or recesses in false ceilings. The two key points remain the floor with the constraint of lowering acceptable loads and the ceiling height available for the installation of related elements: flour hoppers and tank elevators.

Scalability is often overlooked, but a kneading machine is a long-term investment. Therefore, it is important to overestimate current needs to accommodate future requirements. Especially considering that the price-to-capacity ratio is not directly proportional, so a machine with 20% higher capacity will not cost 20% more.

This point can be related to the previous one about future-proofing, by ensuring there is space available for a second machine when needed.

Until recently, the kneading process relied on duration and mixing cycle speeds. However, for several years, scientific theory has indicated that measuring the energy incorporated into the dough is more relevant. Indeed, time and kneading speed remain incomplete, as they do not indicate with what intensity the dough is being kneaded.

Newer, more modern control systems now allow for setting mixing cycles based on kneading intensity, moving away from the traditional concepts of time and speed.

Hygiene in the bakery is no longer optional, given the risks of contamination in finished products. That’s why today, kneading stations offer numerous options in terms of cleanability. Of course, easy access and the absence of dough retention areas have become standard in modern equipment. However, some machines offer CIP (Clean In Place) units, providing automatic cleaning cycles.

Conclusion

The goal of this article was to impartially outline all the available kneading technology options today and associate them with the equipment solutions offered in the bakery and snacking markets.

The options are numerous, with many advantages and disadvantages. To avoid making the wrong choice, it’s crucial to start with your needs and product and match them with the right machine, not the other way around. Hopi Consulting supports you in this process by offering custom technical support, independent advice, and a 100% bakery industry approach. Discover our technical support solutions on our website.

So, what about you? Which type of kneading will you choose?

This article was written by Hopi Consulting, the engineering dedicated to Bakery, Pastry, and Viennoiserie. Discover more articles on the Hopi Consulting blog, dedicated to the bakery industry.