Introduction

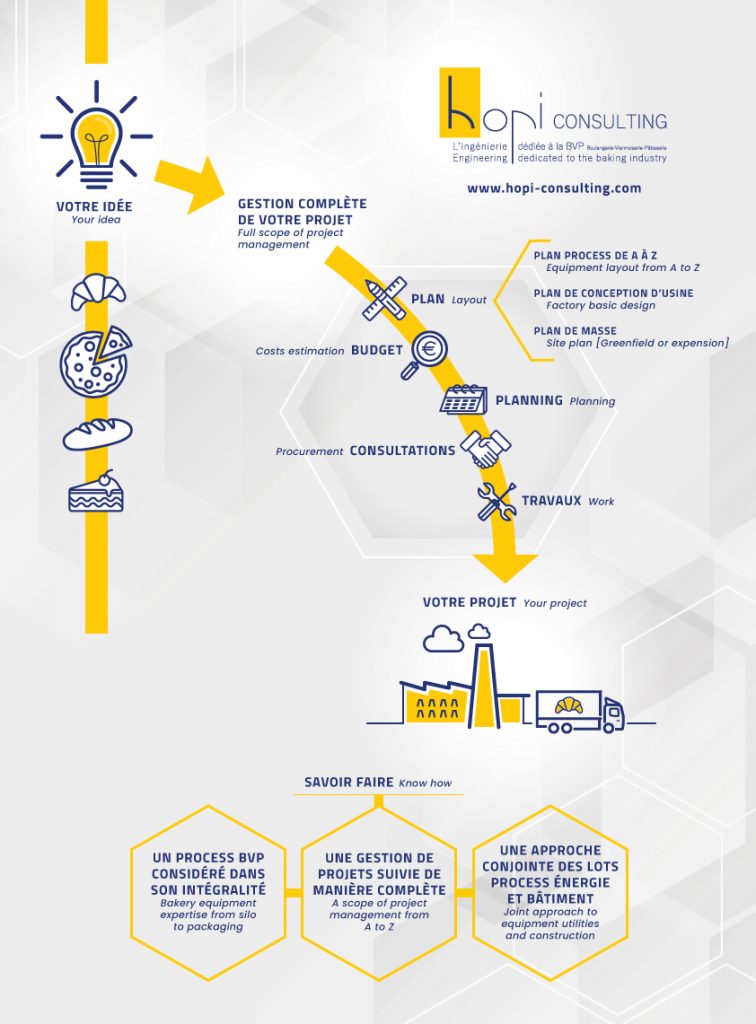

Are you looking for a clear and understandable description of the industrial pastries production process ?

Here is a step by step overview of the production diagram including each types of sweet pastries as well as pies, cakes, layer cakes, French pâtisseries (éclairs, religieuses,…), American pastries (Muffins, donuts,…), crepes and pancakes…

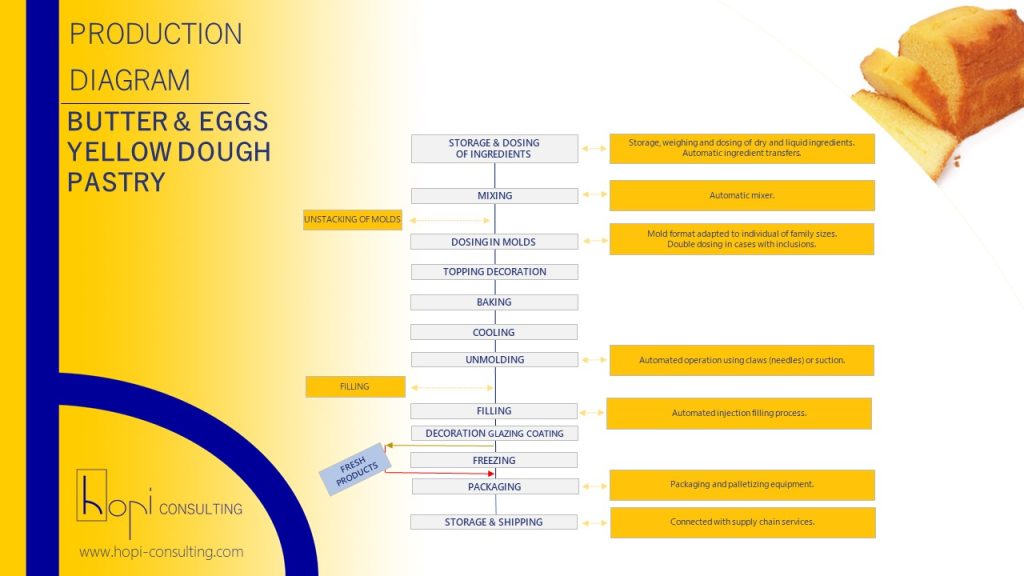

All steps of the production flowsheet are covered: from the raw material storage and dosing stages, to the mixing and whipping steps, filling, topping operations, baking, cooling, freezing, slicing into portions and finally packaging before shipment stages.

Special thanks to Arnaud DURAT, trainer and consultant at GWASTELL CONSEIL, for his support in writing this article.

If you want to know more about other industrial bakery process, don’t hesitate to have a look at the article about puff products and bread products in our technical blog.

In order to make this article as understandable and interesting, Arnaud and I decided to create a four-part presentation, covering the following family products :

Choux pastry

Pies

Cakes

Yellow dough pastry

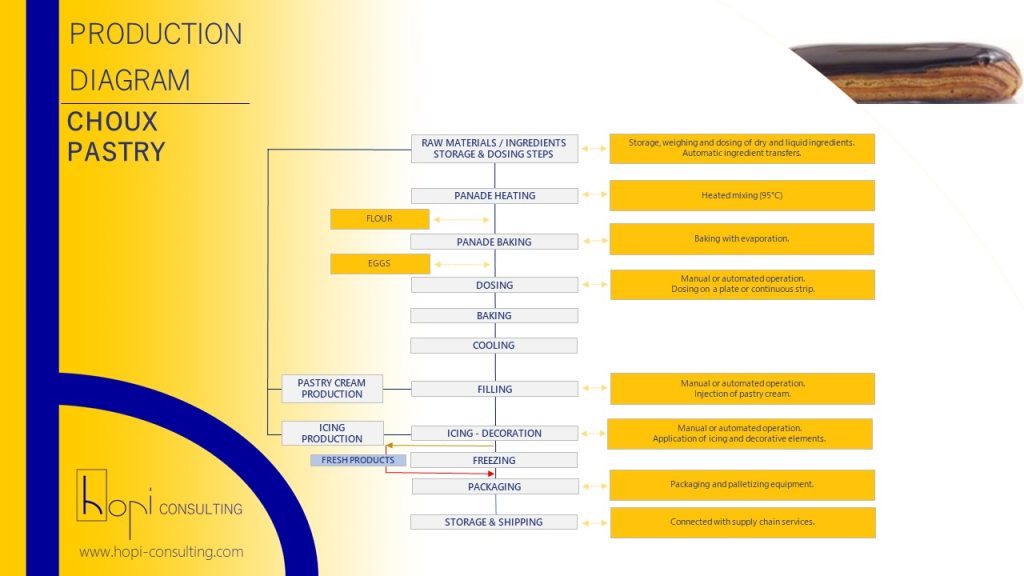

Choux pastry

Choux pastry is the first product family we decided to detail. This range includes cream puffs, éclairs and religieuses with various flavors (coffee, chocolate, fruits…), salambos, Paris-Brest and finally chouquettes.

Historically called “hot pastry”, due to the drying stage overheatet, it became known two centuries later as “choux” pastry cream puff. A crucial step is releasing steam before the final baking. Once baked and dried, the dry shells are filled with pastry cream and then decorated with icing for éclairs, religieuses, and salambos. Chocolate and coffee icing are now challenged with new fruit tastes as well as strawberry, mango but also cinnamon…

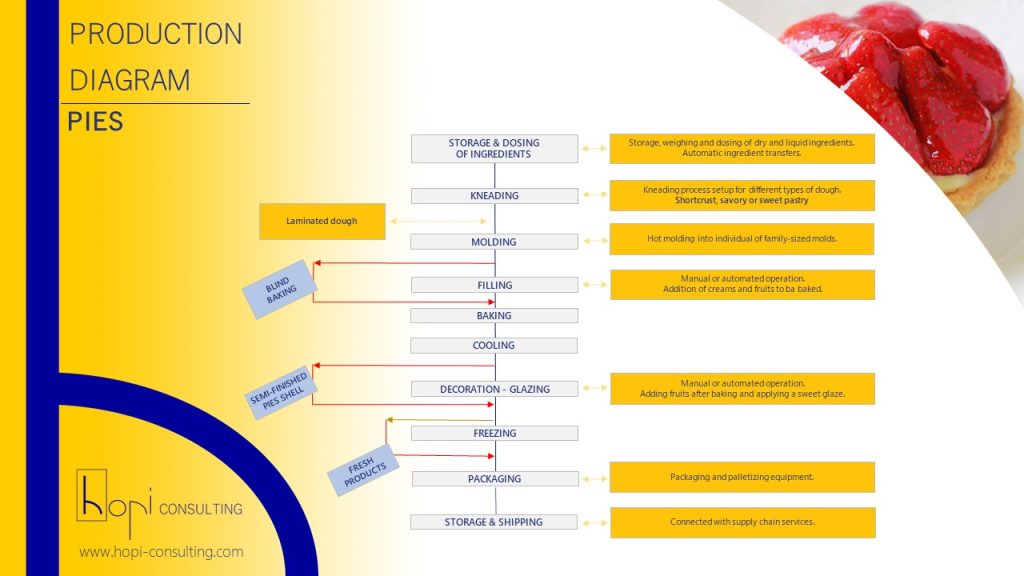

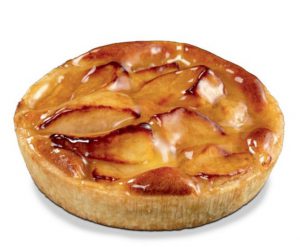

Pies

It is difficult to pinpoint the exact origin of pies, but they undoubtedly represent an ancient dish, whether savory or sweet. A pie or a tart can be defined as the combination of dough placed in a dish with a filling, all destined to be baked.

Sweet tarts are characterized by their great diversity. First, the type of dough: puff pastry, shortcrust pastry, sweet pastry, or biscuit pastry. Then, the almost limitless combinations of fillings and decorations, often based on creams and/or fruits. The dough is always baked, but the fillings may or may not be baked (as with apple tart or strawberry and red fruit tarts).

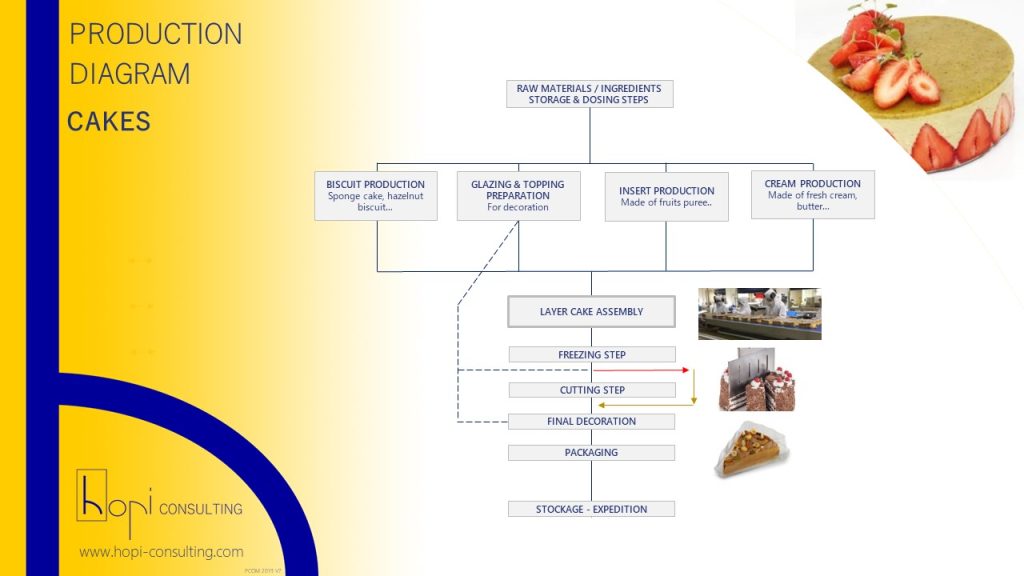

Cakes

This is the most challenging product family to describe. Even though the principle is simple – layering a biscuit and cream repeatedly, then decorating the whole – the variety of techniques and products is vast.

Products can be categorized by shape: there are round or square family-sized layered desserts and individual portions in triangular, round, or rectangular shapes. Thanks to cutting technologies (water jet or ultrasonic cut, which we’ll discuss later), shapes are now limitless: Christmas trees, Easter bells, stars…

They can also be classified by the type of biscuit used: sponge cake, Joconde biscuit, dacquoise, or butter puff pastry (as in the “mille-feuille”).

Lastly, the choice of creams, fillings, and topping personalizes the pastries, making them distinct: fraisier, opera, mocha, mille-feuille, and charlotte are classics of French pastry, but many more modern options are also among the most produced and sold layered desserts each day.

Butter and eggs yellow dough pastry

This category includes all products made from liquid yellow butter and eggs dough, such as madeleines, cakes, and long-life French pastries (quatre-quarts, marble cake, gingerbread…) and American ones (Muffins).

All these products are made off large portions of butter and eggs, and are poured into molds to give them their final shape after baking. They are then sold either in family-sized portions (bars or cakes) or as individual servings (madeleines). Product and packaging innovations have recently expanded the range of madeleines with new flavors, appearances, and tastes.

Crepes and Pancakes are made with a similar production process except for the baking step. They are spread roundly on a hot griddle and then filled with cream or sugar.

Focus on key industrial stages

Certain steps are essential in the industrial pastry production process. Here is a technical description of most common ones.

Raw materials storage and dosing step

This is the first step in the production proces. The preliminary step is to store these ingredients before being used.

Different storage methods exist: bags or similar containers are delivered on pallets, which is a logistical standard among all manufacturers. They can be delivered as bulk raw materials in tankers and stored into silos or tanks, which can hold several tons of flour, sugar, or certain liquid ingredients like chocolate. Liquids may be supplied in smaller quantities (syrups, creams…) and delivered into 1000-liter containers or smaller barrels.

If you want to learn more about ingredient storage and dosing, don’t hesitate to visit our technical blog dedicated to the baking industry.

Mixing step

This stage is fundamental: it is much more than just an operation of mixing the ingredients of a recipe.

First and foremost, the mixing step is crucial for accurately dosing the recipe ingredients. Then, mixing plays an essential technological role in texturing the product: hydrolysis, oxidation, and, most importantly, starch gelatinization occurs during this stage. Dough is mixed in large-scale mixers, with mixing speeds adjusted depending on the recipes.

In addition, these industrial mixers meet two other critical needs. First, foaming machines introduce air (whipping) into the recipe to give the necessary lightness to certain mixes. Conversely, vacuum mixers remove air from the mix, making it perfectly homogeneous and dense.

Second, double-jacketed thermal mixers allow hot mixing, promoting reactions such as starch gelatinization, which requires a high mixing temperature (>80°C). These mixers have double-jacket tanks heated either electrically or with hot water or steam. Some mixers offer the ability to cool the mix quickly after hot mixing by circulating cold water or cold glycol through the double jacket to decrease the temperature of the hot dough.

Lastly, hygiene and cleanability of industrial mixers are crucial. These machines can be disassembled for independent cleaning in the factory’s cleaning room. Some mixers also propose built-in cleaning-in-place (CIP) systems for automatic and standalone cleaning process. However, the cost, space requirements, and cleaning effectiveness in hard-to-reach areas should be considered.

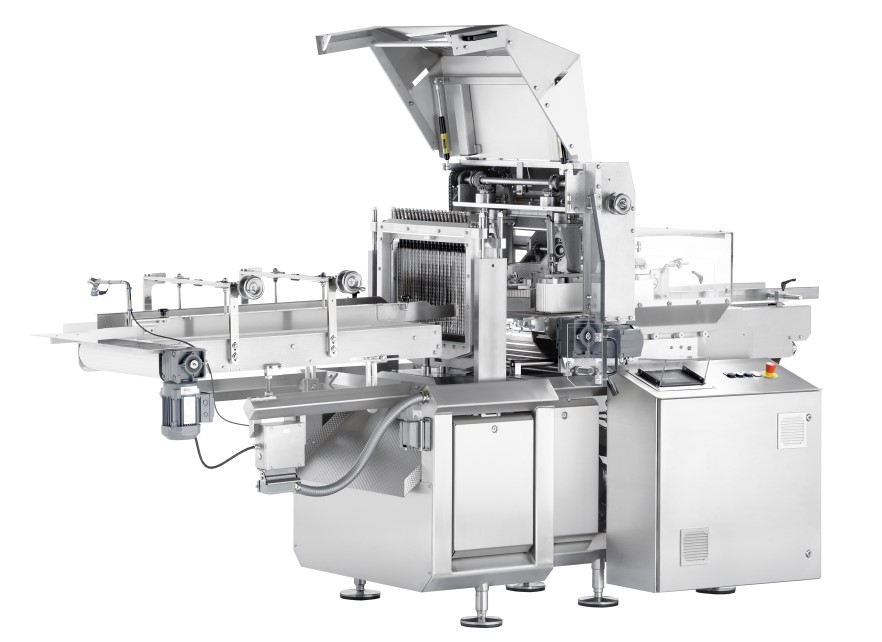

Portioning and shaping

Although these two processes are often grouped together, we’ve chosen to differentiate them clearly.

Shaping gives the pastry its desired form. It is usually done with raw dough (choux pastry, cake batters, biscuits…), aiming to replicate the pastry chef’s actions with a piping bag or spatula. The process is performed with a shaping machine, either in molds (indexed shaping) or directly on an oven conveyor (e.g., for choux pastry).

The industrial machines are composed of a hopper that receives the preparation. This hopper feeds the production line and empties either by gravity or pressure toward feeding rollers. The output is through a smooth bar for biscuit sheets or through multi-point nozzles for choux pastry.

Portioning refers to the fillings and can be done using the same equipment as shaping (hopper, feeding rollers, volumetric portioning). Volumetric dosing ensures consistency in the density of the fillings.

For liquid fillings (fondants, ganache, syrups…), rotating valves can be used to close the flow between doses and prevent drips.

Cutting

Most pastries sold as individual portions, except for choux pastry products like éclairs or religieuses, come from a larger semi-finished product cut in individual parts.

The product might be family-sized before being sliced, such as large tarts and cakes. Or it might be a larger semi-finished product specifically designed to be divided into individual portions, such as framed layered desserts.

Cutting must be operated without damaging the final individual portions. Waterjet cutting technologies require only frozen pastries, but Ultrasonic cutting can be used with ambient pastries. The challenge is also to carry out this cutting stage at the right capacity with no impact on the production line speed and ensuring hygiene and food safety.

Ultrasonic cutting technology :

This method uses a blade vibrating at a very high frequency. The micro-vibrations allow delicate slicing without damaging the product. Ultrasonic cutting is highly precise and minimizes contact with the product, improving hygiene. However, it is limited to straight, linear cuts. This technology is the one to make pies portions for example.

Waterjet cutting technology :

Here, high-pressure water is projected through fine nozzles to cut the pastry.

Water jet cutting is dedicated to frozen pastry products only. It offers unlimited shape possibilities (Easter bells, Christmas trees, stars…). However, peripheral trimming may limit shape choices, and high-pressure equipment requires careful maintenance.

Blade slicer technology :

This mechanized cutting system is well-suited for sliced cakes. Products are pre-arranged and directed to a blade frame slicer. The blade design and settings define cut quality and slice thickness. This robust system effectively slices fragile products with sensitive ingredients (e.g., fruit cakes), while minimizing crumb buildup.

Conclusion

Arnaud DURAT and I aimed to cover the broad range of products in the industrial pastry sector and detail their production processes. We focused on three key stages: mixing, shaping/dosing, and cutting, while simplifying the representation of processes for clarity.

The diversity of today’s pastries and the dynamic nature of industrial innovation continually push the development of new manufacturing techniques and production methods. We will continue to explore these advancements in future articles.

Many thanks to Arnaud Durat of GWASTELL CONSEIL, for his active participation in writing this article.

This article was written by Hopi Consulting, engineering dedicated to the baking industry. Discover more articles on the Hopi Consulting blog dedicated to the baking industry BVP.